QUALITY CONTROL

#1 Pre-Production Quality Control

At Leezon, quality control begins long before the first batch is produced. Every step from ingredient sourcing and packing material selection to air purification, water treatment, and environmental control is strictly monitored, recorded, and coded to ensure full traceability. Our goal is to guarantee that only qualified materials enter the production process.

Raw Material Inspection

All raw material suppliers are required to provide Certificates of Analysis (COA) and detailed test reports. Upon receipt, Leezon’s QC team conducts independent verification testing, including purity, appearance, and safety evaluations. Only materials that meet both internal and client-specific standards are released for production.

WATERER PURIFICATION

Leezon’s factory is designed and constructed in full compliance with GMP standards, equipped with a Class 300,000 purification workshop. Our multi-stage water purification system, including reverse osmosis and UV sterilization, ensures that all process water meets cosmetic-grade quality standards, safeguarding product purity from the very beginning.

AIR PURIFICATION

Clean air is critical to high-quality cosmetic manufacturing. The production environment is equipped with HEPA-filtered ventilation systems to maintain cleanroom conditions and prevent airborne contamination. Air quality and pressure differentials are continuously monitored to ensure compliance with industrial hygiene standards.

PACKING MATERIAL INSPECTION

All packaging suppliers undergo strict qualification and rating procedures. Upon delivery, every batch of containers, tubes, and caps is visually and mechanically inspected. Our QC team performs random sampling and dimensional verification before approved materials are coded, documented, and sent to the packaging material warehouse.

ROOM TEMPERATURE / HUMIDITY CONTROL

Temperature and humidity in the production and storage areas are precisely controlled and continuously recorded. Since elevated temperature or humidity can cause microbial growth, our QC team monitors conditions daily to ensure an optimal environment for safe and stable product manufacturing.

#2 DURING PRODUTION QUALITY CONTROL

Quality assurance continues throughout every step of the production process. The QC team performs on-site inspections, monitors equipment and environmental parameters, and ensures all operators follow Good Manufacturing Practice (GMP)standards. Every record is documented in real time for traceability and accountability.

MACHINE STERILIZATION

Before each production run, all machinery, including mixing and filling equipment, is thoroughly cleaned and sterilized according to SOPs. This prevents cross-contamination and ensures a hygienic production environment.

SPOT INSPECTION

QC staff conduct periodic spot checks during blending, emulsification, and filling processes. They verify formula accuracy, process parameters, and product consistency to ensure that every batch meets the intended quality standards.

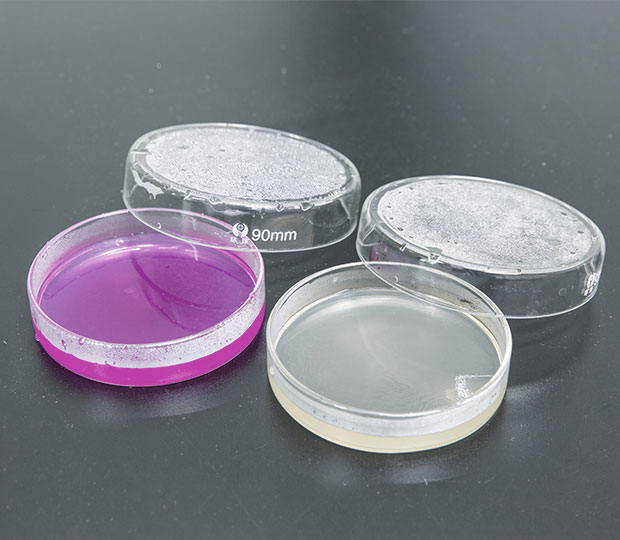

Semi-Finished Product Sample Testing

After emulsification, samples of semi-finished products are taken for both physicochemical (pH, viscosity, appearance) and microbiological (bacteria and mold) testing. Only batches that meet specifications are released for further production.

Semi-Finished Product Sample Coding & Reservation

Each sample is coded, labeled with batch and date information, and stored in a controlled environment for reference. This practice allows Leezon Cosmetics to trace back production conditions at any time and ensures long-term quality monitoring.

#3 FINAL PRODUCTION QUALITY CONTROL

Once filling and packaging are completed, finished products undergo a series of final quality assurance tests to confirm they meet all technical, safety, and stability standards before shipment. This stage ensures that every product leaving Leezon’s facility is safe, consistent, and of premium quality.

Finished Product Sample Testing

Finished goods are sampled for physicochemical and microbiological testing, confirming compliance with both GMP and client specifications. No product is approved for shipment without full test verification and QC sign-off.

Finished Product Sample Coding & Reservation

Each finished product sample is coded, dated, and stored under controlled conditions for a minimum of three years. Our chemists regularly inspect and record observations on product appearance, stability, and odor. If any deviation occurs, immediate corrective actions are implemented to maintain product integrity and continuous improvement.